Cross Out Cross Contamination

Cross contamination is a major risk factor contributing to foodborne illness, but there are steps that you can take in your foodservice operation to mitigate the risk. In this blog, we cover the basics of cross contamination, the risks that result, and sources of cross-contamination so that you can understand the serious risk it presents. In the next blog, strategies to lower this risk will be covered.

What is cross contamination?

Cross contamination is the spread of pathogens (bacteria or viruses) from one surface to another that at some point contacts food. Those surfaces can be hands, equipment, counter tops and cutting boards, people, and even other foods.

Cross contact is a related term that we should talk about, too. Cross contact is focused on the spread of food allergens. Cross contact occurs when a food that contains an allergen (peanuts, eggs, wheat, etc.) contaminates food that will be eaten by someone with a food allergy. This is an important topic to discuss because of the growing numbers of individuals who suffer from food allergies. The eight most common food allergens are milk, eggs, peanuts, tree nuts, wheat, soy, fish, and crustacean shellfish. If you have a customers with a food allergy, it is critical that food they are served does not come in contact with the allergen of concern to them.

Risks Associated with Cross Contamination

Cross contamination present many potential risks for causing a foodborne illness. If you have been following news related to food safety, you know that there have been a number of outbreaks due to the Hepatitis A virus. And, no winter goes by without a number of cases of Norovirus (for more information about Norovirus, view our 2017 webinar on the topic at here.)There certainly is a great deal of risk in the environment for contamination. Consistent in most every discussion we will have with you is the idea of risk and mitigating or minimizing risk. We want you to serve safe food to protect your customers and your brand. The Centers for Disease Control and Prevention (CDC) is involved in monitoring foodborne illness outbreaks. The investigators for outbreaks do extensive evaluation, testing, and interviews to try to determine the cause of any outbreak. The investigation outbreaks are submitted to CDC, who maintains a database and periodically looks into the main causes of out breaks. Based on outbreak data, CDC identified the top five broad categories as foodborne illness risk factors:

- Food from unsafe sources

- Inadequate cooking

- Improper holding temperatures

- Contaminated equipment

- Poor personal hygiene

Two of these foodborne illness risk factors are directly related to cross contamination: contaminated equipment and poor personal hygiene.

Sources of Cross Contamination

There are several ways that food can be contaminated:

- From Hands to Food

- From Hand Contact Surfaces to Food

- From Food Contact Surfaces to Food

- From Food to Food

- From People to Food

Let’s talk about a few specific examples of how cross contamination can occur.

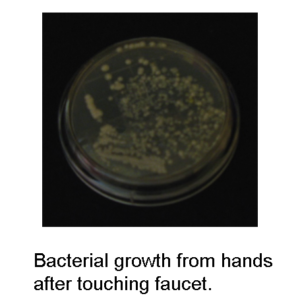

Hands—Hands can be a source for cross contamination of food—that is why foodservice operators should be fanatics about good hand hygiene. Handwashing, with a focus on the “when” and “how” can be an important mitigation factor for cross contamination. Just one example of how technique can contribute to cross contamination is shown in the picture below. Foodservice employees can use the greatest techniques for handwashing and do a perfect job, but if the sink handle is contaminated and they touch it after handwashing, then their hands are now re-contaminated. That is why it is a best practice to use a disposable towel to turn off the handle after handwashing. Otherwise, hands most likely will be contaminated when they turn those knobs!

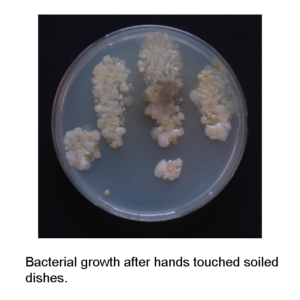

Soiled dishes—Employees complete many tasks and often forget about handwashing between tasks. Below is a picture of a petri dish showing bacterial growth from the hands of someone who had just handled soiled dishes. If that individual then handled a food item or touched a work surface, cross contamination (disease-causing microorganisms or germs) could occur. This illustrates how important handwashing is between tasks and how important it is to keep clean and dirty areas separate.

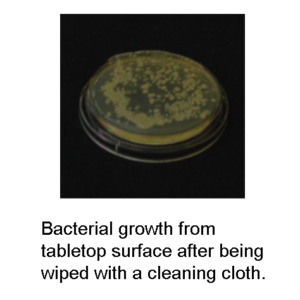

Contaminated surfaces—There are many surfaces in a foodservice operation that food directly touches—countertops, cutting boards, serving utensils, dishes, etc. There are also many surfaces that may come in contact with hands that are working with food—glove boxes, refrigerator handles, etc. Below is an example of the bacteria present on a tabletop after it had been wiped with a cleaning cloth. This just goes to show that “how” cleaning occurs affects the effectiveness.

All photos are courtesy of Iowa State University Extension and Outreach Food Safety Project

People—Even your employees and customers can be sources of contamination. Think about a self-service food station, such as a salad bar, where multiple people handle the serving utensils (or even the food). When someone sneezes, many contaminants become airborne and potentially land on the food. Even with sneeze guards, droplets can sneak by. The Hepatitis A outbreaks I mentioned earlier were found to have been spread by individuals who were infected and who did not wash their hands adequately. There seems to be a hundred (or more!) ways people could be a source of contamination.

Being aware of the risks associated with cross contamination can guide foodservice operators in developing policies and procedures to reduce the likelihood of a food borne illness from occurring.

In the next blog, Mitigation Strategies for Minimizing Cross Contamination will be presented. This information will be helpful for developing policies and procedures for your operations, and for teaching and supervising employees. Be sure to check for the blog in the middle of the month.

Be Safe, Don’t Contaminate!

Please email us questions or comments to foodsafety@foodhandler.com

READ MORE POSTS

Why Canning in Foodservice Really Isn’t a Good Way to Preserve Fresh Produce

Canning has long been a trusted method for preserving fresh produce, offering a way to extend [...]

Managing Food Safety During the Foodservice Holiday Rush

The holiday season is a time of increased activity and demand in foodservice operations, from catering [...]

Ongoing Outbreaks: What We Can Learn from the Most Recent Carrot and Cucumber Outbreaks

Last month in our blog, we highlighted the recent E. Coli outbreak stemming from onions served [...]

The Hidden Dangers: Allergens in Your Foodservice Operation

It has been a while since we have addressed or discussed allergens in the blogs. In [...]