SafeBites Time and Temperature Control: Why & When

Hi Everyone – Cathy here. Having written the SafeFood Blog for Iowa State University for over ten years, I am happy to have the opportunity to work with FoodHandler in my retirement. Jeannie and I share with FoodHandler a passion for making sure food served is safe.

You might recall in the June blogs, Jeannie presented the Top 5 reasons why food becomes unsafe, and she discussed controls for two of those in efforts to reduce risk of cross contamination leading to a foodborne illness.

In this month’s blog, the topic of preventing temperature abuse of foods will be covered. This week, the focus is on the “why” and “when” of time and temperature controls. The second blog in July will identify some action steps that can be taken by foodservice employees to control for time and temperature abuse of foods.

Why is time and temperature control for foods so important? For one thing, it contributes to quality of food. Keeping hot foods hot and cold foods cold, and serving food as close as possible to when it was prepared enhances quality. Who wants to eat a dry hamburger, a cool bowl of soup, or wilted lettuce?

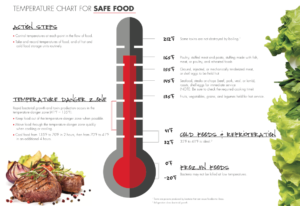

In addition to quality, temperature controls that minimize time certain foods are in the temperature danger zone (TDZ) mitigate the risk of bacteria growing to harmful levels. Temperature Controlled for Safety foods, or TCS foods (which were previously known as potentially hazardous foods) have characteristics that are especially conducive to rapid growth of harmful microorganisms. Rapid growth occurs when the food is in the TDZ. The TDZ is that temperature range between refrigeration (below 41° F) and hot holding (135° F or higher). The “super” TDZ is between 70° F and 135° F. It is in this temperature range where reproduction of bacteria takes place at accelerated rates. That is why proper cooling of hot foods is so important. Because of that rapid growth, the longer foods are in the TDZ, the more bacterial cells will be present, thus likely causing an illness to whoever eats the food. It really isn’t complicated!

In operations, strategizing preparation and holding processes to minimize exposure in the TDZ is the goal. (More on the How To’s next time). FoodHandler® recently updated its Temperature Chart for Safe Food. Consider posting this chart in your kitchen to remind staff of the importance of time and temperature in their daily work.

The other question is when should temperature controls be in place? The simple answer is ALL THE TIME! The general rule of thumb is a total of four hours exposure to the TDZ. But keep in mind the clock is ticking when foods are delivered to the loading dock and before placed into storage, when foods are pulled from refrigeration or freezer during preparation, and after menu items are prepared but before service. Newer versions of the Food Code provide guidance on using Time as a Public Health Control (TPHC), which was previously referred to as TILT (Time in Lieu of Temperature).

In a nutshell, TPHC allows for hot or cold food holding without temperature controls (no refrigerated salad bar for instance), as long as foods are discarded at the end of the service period. (If food waste is a concern for your operation, then that is a point to consider in whether or not to adopt TPHC.) TPHC does have some requirements that must be met. One, it must be documented that food was at the proper temperature before pulling from the storage unit AND the food item must be labeled with either the time pulled from temperature controls or the time product is to be discarded. Second, cold foods can never exceed 70° F during the 6 hours allowed for the service period. Hot foods can be held without temperature controls for up to 4 hours.

Next time we will get into some strategies on how to control for temperature abuse in your operations. Hopefully the information in this blog helps provide the background on why it is important for everyone in the operation to be aware of the risks associated with temperature abuse of certain foods throughout the day and recognition that attention to time and temperature monitoring is continuous.

As Jeannie noted, we like to talk about food safety issues and concerns, so please don’t hesitate to shoot us an email with any questions, comments or concerns at foodsafety@foodhandler.com

READ MORE POSTS

Halfway Gone, A Mid-Year Food Safety Check-up for your Foodservice Business

July is often a time when a portion of us in the foodservice business are at [...]

From Farm to Fork: Knowing the Importance of Food Origins

In the foodservice industry, maintaining high standards for the food that comes into your back door [...]

Brushing up on Hygiene: Are Nail Brushes the Unsung Hero of Clean Hands?

Last month, I focused the discussion within the blogs on handwashing. One aspect of handwashing that [...]

Clean Hands, Safe Eats: Considerations to Improve Handwashing Compliance

In my blog earlier this month, I discussed a bit of the art and science behind [...]