SafeBites Time and Temperature Control: How To’s

Welcome back! In the last blog I gave the low down on temperature controlled for safety (TCS) foods and the temperature danger zone (TDZ). The focus of this blog is all about control of time and temperatures of foods in your operations. You might say we are discussing Control Issues! Kidding aside, knowing that temperature abuse is a leading cause of foodborne illness, it only makes sense to pay attention to the time that TCS foods are in the TDZ (remember, that is between 41° F and 135° F). FoodHandler® recently updated some useful time and temperature documentation tools.

These logs provide guidance about when to check temperatures of foods and food storage units with a structured format that includes the necessary information needed for record keeping.

As operators, there needs to be a focus on the time TCS foods are in the TDZ controls for both quality and safety. All staff should be alert as food flows through the operation – from purchasing to service. Operations make every effort to purchase from reputable suppliers who are paying attention to temperature controls. Before foods are accepted, it makes sense to verify that the food delivered meets the quality and quantity specifications that was ordered. Part of quality checks involves temperature. If a ready-to-eat bagged salad green arrives at 50° F, then it is advised that product not be accepted into the custody of your foodservice, as it is unknown how long this TCS food was in the TDZ. Remember, once product is accepted, you own it! After product is accepted, don’t let it sit on the loading dock for extended periods of time as that not only can lead to temperature abuse, it negatively affects quality, AND there is potential for theft, or worse, intentional contamination of the food. Placing foods into the proper storage unit as soon as possible provides control. A new Refrigerator Storage and Food Placement poster from FoodHandler® reinforces these tips as well as controls against cross contamination.

Include in contracts with vendors that deliveries will not be accepted during meal times to ensure good receiving practices are followed and to allow time for proper storage. Also document when a delivery is not acceptable as this can provide information useful when making decisions about vendors.

If frozen foods need to be thawed for use (like 30 lb. containers of eggs), be sure these are pulled with enough time to thaw under refrigeration. Large containers will not thaw overnight; plan ahead and allow several days. Communicate on production schedules when foods should be pulled and placed in the cooler. Of course, some frozen foods, like hamburgers, can be panned and cooked from the frozen state.

During preparation, encourage staff to think in terms of batches. Batch cooking, also known as just in time service or a market display concept, has benefits of improved quality and appeals to customers’ sense of freshness and customization. It also makes sense from a safety perspective. Think about it. Even if the forecast or production order is for 100 ham sandwiches, it doesn’t make sense to bring out all the ham needed to complete this order at once. Rather, encourage staff to bring out smaller amounts. Or if pans of hot food product are to be served, stagger the cooking schedule; you may find that the last pan or two is not needed! This may have positive impacts on food costs as well! There are some good training resources in the Do Your PART series from Iowa State University.

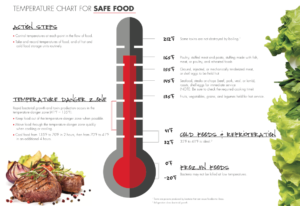

If there is hot food left over after service and the operation decides to store for future service, it is critical that proper cooling occurs. Remember the “super” TDZ is between 70° F and 135° F; therefore, hot food temperatures must drop to below 70° F within 2 hours, and to below 41° F within an additional 4 hours. The FoodHandler® Temperature Chart for Safe Food can provide a helpful, visual reminder.

There are tips on how to meet these standards even if a blast chiller is not onsite. One way is to portion leftover product into smaller units. Another is to put pan in a pan of ice and stir the product. Some operations purchase chill sticks. These are internal ice baths and can lower temperatures of liquid-based foods more quickly. Keep in mind that cooling is not easy to accomplish, so time and temperature monitoring is critical to make sure your techniques are working.

In the last blog, Time as a Public Health Control (TPHC) was mentioned as one option. Remember though, there are certain actions that need to be taken, including documentation of time and temperature that foods were removed from temperature controls of hot or cold holding. The new logs developed by FoodHandler® can be used for these purposes also.

The general rule of thumb is to minimize time TCS foods are in the TDZ. Taking actions to control for temperature abuse also maintains quality of menu items served. The key is planning, and having clear guidance available so everyone knows the proper actions to take. Generally, people are more inclined to follow procedures if they understand why they are in place.

In these last two blogs, the why and when of temperature controls, along with some tips on how to do so, have been presented. As a result, you can take control to prevent illness from food in your operation that was temperature abused. In this case, having control issues is a good thing!

Cathy

READ MORE POSTS

Clean Hands, Safe Eats: The Art and Science of Handwashing in Foodservice Operations

Last week, I had the pleasure of joining one of our FoodHandler partners, Martin Bros. Distributing, [...]

Never Did I Ever…

Yes, I know the real game is “never have I ever”, but that phrase didn’t work [...]

Understanding Food Contamination in Foodservice Operations

Within this blog, I’ve provided a lot of details about the finer points of food safety [...]

The Antibiotic Debate in Our Food Chain

The discovery of antibiotics in medical science is regarded as one of the most important medical [...]