Food Traceability in Foodservice Operations: An Essential, and Soon-to-be Required, Component of your Food Safety Plan

In June, I discussed the importance of having a solid food defense plan, and I provided you some resources for developing or strengthening your food defense plan. As I was writing those blogs, my mind kept turning toward food traceability. While they are distinctly different concepts, food traceability goes hand-in-hand with a food defense program. I would argue for your food defense plan to be effective, you must have an effective internal food traceability program, where you can trace the product back to the supplier (backward traceability), but also be able to trace the product from the supplier to the guest who was served the product (forward traceability).

Forward traceability is often the most difficult for foodservice operators. If you are a commercial restaurant operator, this can be extremely difficult if the guest pays with cash, where you have no records to track who dined in your establishment, let alone what food they may have consumed. In schools and other on-site feeding establishments, it can be made difficult due to the sheer number of guests/students fed daily. You might be able to track who dined in your operation on a particular day, but it generally gets a bit more complicated when you try to answer the question of which guests had a certain product from a particular case or lot number.

For several years, the U.S. food supply was only required to have a one-step forward and one-step back traceability. This meant you had to know where your product came from and where it went once it left your operation. The Food Safety Modernization Act provided the groundwork for the Food and Drug Administration to designate foods for which additional record keeping is required to protect the public health. The New Smarter Era of Food Safety Blueprint, laid out by the Food and Drug Administration included improved traceability as one of the four key elements, along with smarter tools and approaches for prevention and outbreak response, new business models and retail modernization, and food safety culture. These four elements serve as the building blocks for a more digital, traceable food system.

If you think that the changes to traceability will not impact your foodservice operation, think again. While it could still change, I would expect some changes to be coming to the traceability landscape for foodservice operations in the coming years.

If you think that the changes to traceability will not impact your foodservice operation, think again. While it could still change, the proposed rule provides only a few exemptions for foodservice operations. Two of the exceptions require the foodservice operation to have 10 or fewer full-time equivalent employees. Another partial exception is in place for schools who participate in farm-to-school programs under the guidance of USDA, but the rule would require them to maintain records of where the product was sourced for a minimum of 180 days.

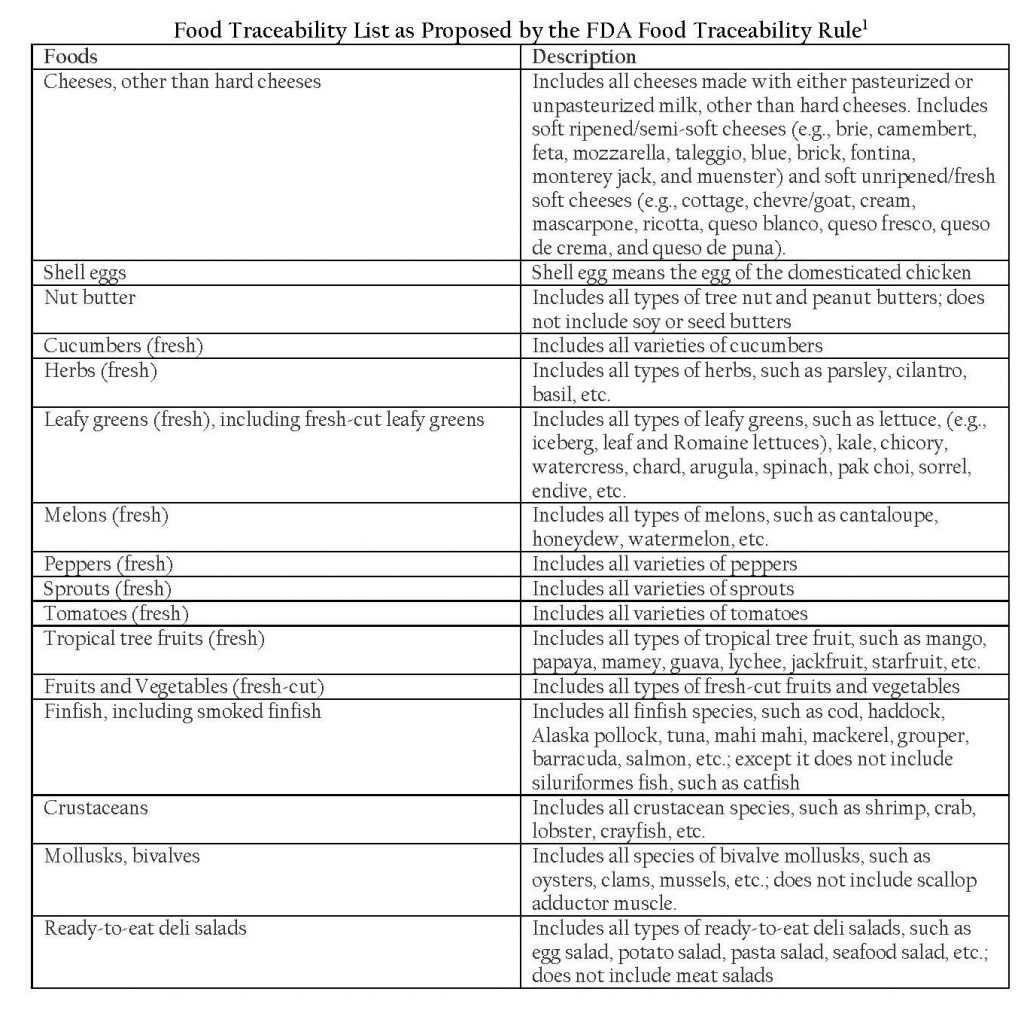

Fundamentally, the proposed rule would require those who manufacture, process, pack, or hold food on a designated food traceability list to establish record keeping data of key elements associated with various Critical Tracking Events. Foods currently on the list are included in the table below.

The end goal of the Food and Drug Administration is to improve the tracking of food to enable end-to-end traceability. To achieve this, records for food product will need to be linked. If a foodborne illness outbreak were to occur, the foodservice operation would be required to provide traceability records in the form of an electronic, sortable spreadsheet to the Food and Drug Administration within 24 hours.

While the proposed changes are currently just that – proposed, I would expect some changes to be coming to the traceability landscape for foodservice operations in the coming years. If the proposed rule is accepted, it would become effective 60 days after publication in the Federal Register. Compliance date for the food industry would be two years after that date.

If you would like to learn more about food traceability, why it is important, how some foodservice operations have embraced traceability, and some tips on getting started – join us for our July SafeBites webinar where I will be presenting more information on Traceability. It is scheduled for July 21 at 1:00 pm. We would love for you to join us.

I hope you have a great 4th of July weekend. Be safe as you travel and enjoy family and friends. Risk Nothing.

[1] Source: Food & Drug Administration. (2021, July 1). FSMA Proposed Rule for Food Traceability. Food Traceability List. Available at: https://www.fda.gov/food/food-safety-modernization-act-fsma/fsma-proposed-rule-food-traceability

READ MORE POSTS

Embracing Technology for Enhanced Food Safety in Foodservice Operations

Technology. We love it, we hate it. I’ve always been fascinated by technology; I remember getting my first Blackberry in the mid-90s and thinking it was the pinnacle of technological advances. Before that, I remember ordering a dictation program in college that was going to revolutionize the way I “typed” my assignments. Looking back, it really wasn’t worth the box that the program came in. Now, we have ChatGPT that will write the entire paper for us!

Meat Color and Doneness: Persistent Pinking

Late in June, my family and I were able to visit the Black Hills, an area of the country in which I have not had the opportunity to spend much time. One evening, as we dined at a local restaurant, I observed a table across the dining room sending back a dinner. While I couldn’t hear the entire conversation and I certainly wasn’t trying to eavesdrop, it was apparent that the customer was unhappy with the cooking of their hamburger and was sending it back because it was too pink in the middle. That immediately brought to my mind the phenomenon known as persistent pinking. A term I became familiar with because of work done by some colleagues here at Kansas State, which they present each summer to a group of foodservice operators who join us on-campus for an in-depth week-long look at all things food safety.

Quat Binding – Why this Can Have a Disastrous Impact on Your Sanitation Program.

In June, I had the opportunity to represent FoodHandler and speak on food safety behavior for customers of Martin Bros. Distributing in Waterloo, Iowa. One of the questions that was asked caught me a little off guard. The question was about quat binding. It caught me off guard not because it was a bad question, but only because it was not something I had previously been asked nor had not yet been exposed to the phenomenon. However, I soon learned that in certain jurisdictions, it is resulting in changes to how sanitizing cloths are to be stored in sanitizing buckets (or not) in the foodservice industry. When I returned home from the trip, I had to dig into it to learn about what quat binding is and how it might impact foodservice operations.

Are Grades for Foodservice Inspections a Good Idea?

I generally try to stay away from controversial topics in my blog, but this is one I thought it might be interesting to discuss. Occasionally on my travels, I will come across a state or a local jurisdiction that requires foodservice inspection scores be posted in the window of the establishment. The idea is to allow would-be customers the ability to see how the foodservice operation in which they are about to eat scored on their latest health inspection.