Cold Chain Management in Winter: Why Cold Weather ≠ Safe

In early January, my family and I returned home from an extended time away to find that one of our freezers, wasn’t quite “frozen”. In fact, it was just on the “warm” side of refrigerated temperatures. When temping the product that was in the freezer, I found that the temperature was in the low 40s. This particular freezer is kept in an outbuilding that is fully covered but has no temperature control. Knowing that the temperature danger zone starts at 41°F and that the product was slightly warmer than that, I thought we were likely safe to refreeze and cook the product later. However, the food safety side of my brain wouldn’t let it go. Was the product in the low 40s for the last hour or the last several days? There was really no way to know, especially since we were gone from our home for close to two weeks. If it were 90°F plus outside, the chances that the product would have stayed in the 40s very long is doubtful. But, given that the temperature outside was hovering around freezing, there was just no way to know how long it was above 41°F with any certainty. So, I ended up pitching the product to keep everyone in our family safe.

In such a situation, one might think, “perfect, everything’s staying cold naturally.” But cold weather doesn’t guarantee safe food. In fact, winter creates some unique cold chain challenges in the foodservice industry that could put your operation at risk.

Winter weather creates deceptive conditions that mask temperature abuse. What feels cold to your hand might still be in the danger zone for bacterial growth. This was certainly the case in our freezer mishap. What initially felt cool to the touch, temped to be in the low end of the temperature danger zone.

…winter weather creates deceptive conditions that mask temperature abuse. What feels cold to your hand might still be in the danger zone for bacterial growth…

Partial thaw and refreeze cycles are especially problematic in winter. Frozen products can partially thaw during loading, transport, or unloading, then refreeze in cold outdoor air before you ever check them. While this cycle may not impact food safety, it does impact food quality and can lead to ice crystal formation that hide previous thaws.

The 2022 Food Code is clear: potentially hazardous foods must stay below 41°F or above 135°F. What may not be so clear is that outdoor temperature doesn’t really count as controlled refrigeration.

Your receiving SOP is your primary defense against compromised product. Start before the truck arrives by communicating with suppliers and carriers. Confirm that refrigerated units maintained proper temperatures throughout transit, verify that seals on refrigerated compartments remained intact, and get an estimated arrival time so staff can prepare the receiving area and minimize door-open time.

When the delivery arrives, conduct a thorough visual inspection before accepting anything. Check all packaging for tears, crushing, or wetness that suggests temperature abuse. Look for excessive ice buildup or frost on frozen items, which often indicates previous thawing. Examine products for signs of partial thaw: soft spots on frozen items, ice cream that’s reshaped in the container, or frozen vegetables clumped together in solid blocks.

Use a calibrated thermometer and check internal temperatures, not just surface readings. For frozen foods, insert the probe between packages or into the product itself when possible. Frozen foods must be…well, frozen! Refrigerated items must be 41°F or below. Check multiple items and multiple locations in the delivery, especially products in the middle of stacks where temperatures may have fluctuated.

Once you accept a delivery, move quickly. Transfer refrigerated items to proper storage quickly. Stagger deliveries when possible so staff can properly inspect and store each load before the next arrives.

Proper storage is only as good as your monitoring system. Install thermometers in the warmest part of each refrigeration and/or freezer unit. This is typically near the door but away from vents that give false readings. Consider purchasing a temperature monitoring system. Most systems can now send direct warnings via text message to cell phones of managers and supervisors to alert them to any issues before they become a situation where you must destroy or dispose of product.

Check and record temperatures of your storage units at least twice daily, once at opening and once mid-day or closing. Increase checks during temperature extremes, after winter storms that may have caused power fluctuations, and any time a unit’s door has been left open. If temperatures drift out of range, take immediate action.

The cold weather of winter creates a false sense of security that can compromise your entire operation. Temperature abuse leads to foodborne illness, product loss, and damage to bottom line and reputation. This week, audit your current cold chain procedures, and verify that all thermometers are calibrated, and temperature logs are current. Diligence now prevents a crisis later. Risk Nothing.

READ MORE POSTS

Food Traceability in Foodservice Operations: An Essential, and Soon-to-be Required, Component of your Food Safety Plan

In June, I discussed the importance of having a solid food defense plan, and I provided you some resources for developing or strengthening your food defense plan. As I was writing those blogs, my mind kept turning toward food traceability. While they are distinctly different concepts, food traceability goes hand-in-hand with a food defense program. I would argue for your food defense plan to be effective, you must have an effective internal food traceability program, where you can trace the product back to the supplier (backward traceability), but also be able to trace the product from the supplier to the guest who was served the product (forward traceability).

Food Defense Plan Resources – at just the right price…

Earlier in the month, I discussed the importance of having a solid food defense plan in place for your foodservice operation. Even if the first version of your plan is not perfect, it is a start. Having plans down on paper will force you to think through the process and ensure the vulnerable points where opportunities exist for possible contamination within the operation are mitigated.

Don’t Turn a Blind Eye to Your Food Defense Practices

Late last week, as I mindlessly scrolled through Twitter, I ran across a Tweet suggesting the #IceCreamChallenge from summer 2019 was the real cause of the Coronavirus spread. Of course, the Tweet was made tongue in cheek, but it did cause me to reflect on that challenge, which had a short life on social media in the summer of 2019.

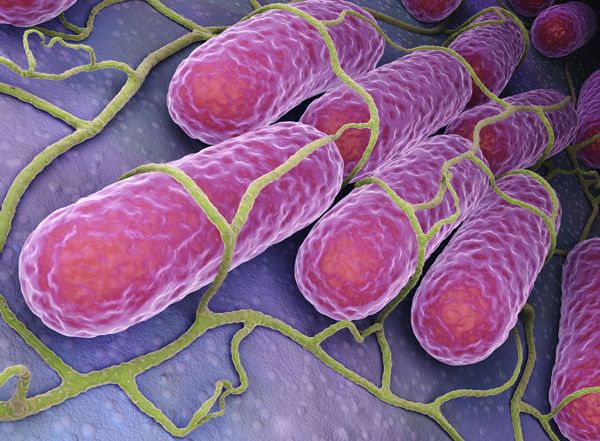

Salmonella and Listeria monocytogenes: Serious Threats to the Safety of Food

Earlier in the month, I mentioned the top microbial enemies we all face in foodservice operations, E. coli, Campylobacter, Salmonella, and Listeria monocytogenes. While we discussed E. coli and Campylobacter, we did not get around to discussing Salmonella or Listeria monocytogenes.